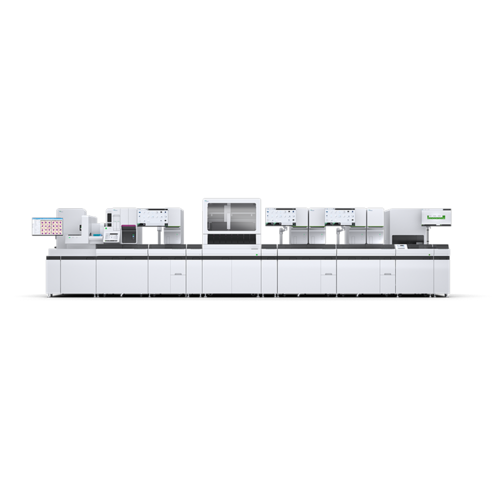

BT-50

Barcode terminal with added innovative functionalities – for XR-9000 automation lines

- Scheduled system start-up and automated QC handling eliminates waste in the process

- Reduces manual efforts for quality control by automating storage and preparation of XN Check

- Integrated cooler unit for XN Check and storage compartment for Cellclean Auto

- Flexible, automated shutdown and cleaning with Cellclean Auto

- Enables a higher level of automation to alleviate staff shortages

BT-50: the new milestone for a worry-free, walk-away laboratory workflow

The BT-50 barcode terminal contributes to a worry-free, walk-away and standardised laboratory haematology workflow by automating a range of tasks that until now had to be performed manually by the laboratory staff.

In addition to the barcode-reading function inherited from its predecessor BT-40, the BT-50 stores the XN Check vials in its integrated cooler unit and the Cellclean Auto vials in its storage compartment, and manages the automated transportation of vials containing XN Check and Cellclean Auto to the individual analyser modules. BT-50 offers highly flexible schedule settings for cleaning and XN Check measurements to ease the mind of the operator.

The BT-50 is a truly innovative module in the haematology field with an automated XN Check management functionality and automated start-up and shutdown possibilities, all of which contributes greatly to reducing manual operations.

BT-50: much more than a barcode terminal

- A walk-away concept in haematology with the innovative automated start-up and XN Check management function to minimise manual tasks which previously had to be performed by the laboratory staff.

- Flexible automated shutdown of either the whole automation line or individual, selected modules to save resources.

- On-board management of XN Check and Cellclean Auto vials including waste management of empty vials.

- Automated cleaning of the analysers based on measurements as well as scheduled cleaning ensures their consistent performance and eases the mind of the operator who has less manual work to take care of.

- The BT-50 is easily operated via its integrated touchscreen, managing scheduled start-up, automated XN Check measurements and the cleaning of Sysmex analysers.

Automated start-up

- Scheduled start-up of the XR-9000 automation line

- Automated QC analysis can be initiated after the system has started automatically.

- The start-up process starts 30 minutes before the specified time.

Automated QC handling

- Storage of XN Check vials in the BT-50’s integrated cooler unit

- Automated and scheduled QC measurements include incubation of the vials for 15 minutes, transfer to the analyser modules, mixing, measurement, and return to the storage.

- Should the number of remaining tests from a vial be insufficient, a second vial is automatically taken out of the cooler unit. Should no second vial be available, an alert is triggered.

Automated cleaning

- Storage of Cellclean Auto vials in the BT-50

- Cleaning can be scheduled for any date, time and specific analyser module.

- Additional cleaning outside the set schedule is possible.

- Automated cleaning in addition based on the number of measurements performed by the XR analysers.

Automated shutdown

- The automated shutdown procedure is highly flexible:

- The whole automation line including the cleaning of all Sysmex analysers

- Only selected Sysmex analysers including their cleaning

- Just a shutdown of the BT-50 itself

| Applicable model | XR-9000 with up to 9 XR modules in the same line |

| Throughput | 1,000 tests/h or 100 racks/h |

| Main features |

|

| Temperature of the cooler unit | 2–8°C |

| Waste bin capacity | 200 vials |

Sysmex Nordic ApS Suomen sivuliike

KPY Novapolis

Microkatu 1

70210 Kuopio

Finland

+358 102999940

![[.FI-fi Finland (finnish)]](/fileadmin/_processed_/f/5/csm_XR-9000_BT-50_Animation_e8c782aa7d.png)